Real Time Oil Monitoring System

Real-time detection of anomalies in lubricant and hydraulic oil

Tan Delta Systems’ oil quality sensor constantly provides precise, real-time oil condition monitoring with its proprietary FSH™ core technology. Tan Delta Number (TDN) indicating the oil condition is output every 2 seconds, and the oil monitoring system stores 800,000 results at all times. The data can be downloaded at any time and easily visualized as a graph. Using this constant oil monitoring system, you can pinpoint when some anomaly has occurred within the oil. (The sensor also records temperature. Temperature changes themselves have no effect on the Tan Delta Number.)

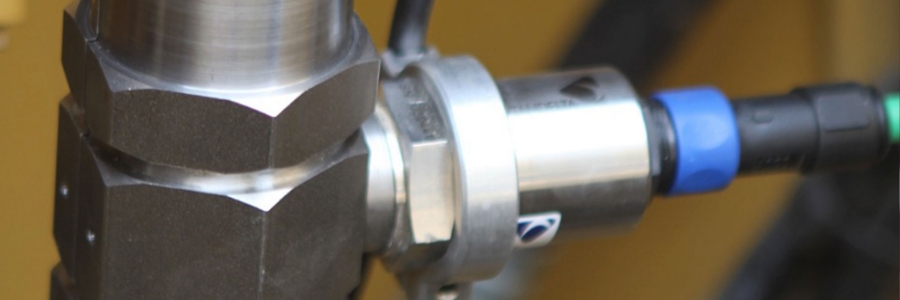

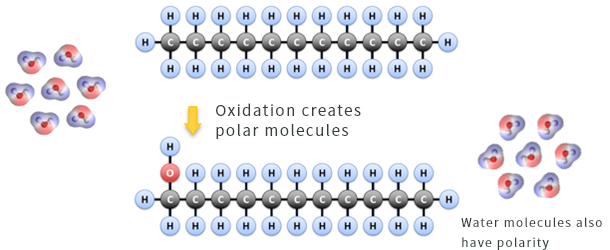

It is very easy to set up. Simply insert the tip of the oil quality sensor, which is integrated with a 1/2 inch male screw, into the oil of the machine which will be monitored. The sensor tip generates a high-frequency AC current (15 times/second) in the oil, measures the oil’s conductivity and capacitance, calculates a correlation value between the two to give a “Tan Delta Number” (TDN). By analyzing in advance the electrical properties of the oil, Tan Delta Systems can ascertain the difference between the new oil and the current state of the oil in use, and this is displayed as an objective index in the form of Tan Delta Number (TDN). Oil contamination due to internal or external factors including metal wear particles, water intrusion, acid value, viscosity change, etc. are reflected in the Tan Delta Number (TDN). An alarm can set which would notify the person in charge when the TDN value passes the alarm threshold.

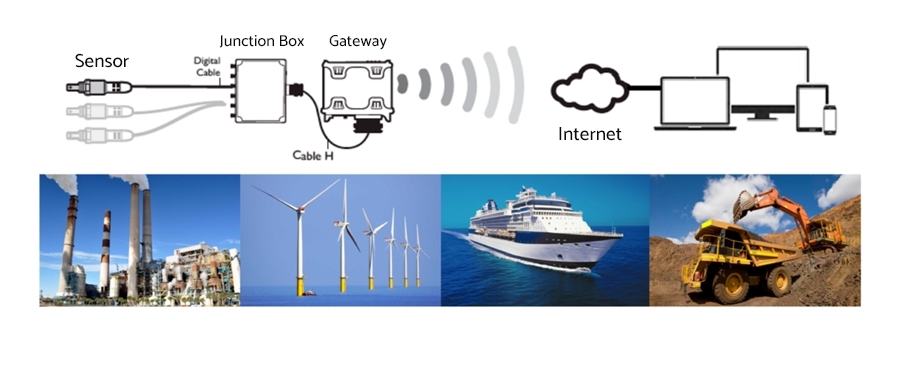

Monitor your oil remotely at all times

This real-time oil monitoring system can be set up so the oil condition is monitored at all times from a remote center. Current levels of oil deterioration can be checked from anywhere in the world through internet access in order to quickly respond any any problem and implement necessary measures to prevent accidents. This can be done for sites such as large-scale plants, wind power generation, ships, heavy mining and construction equipment. Constant monitoring of the oil allows you to eliminate unnecessary oil changes, perform maintenance and servicing at optimal times, and achieve significant cost reductions.

Products

OQSx-G2 Oil Sensor

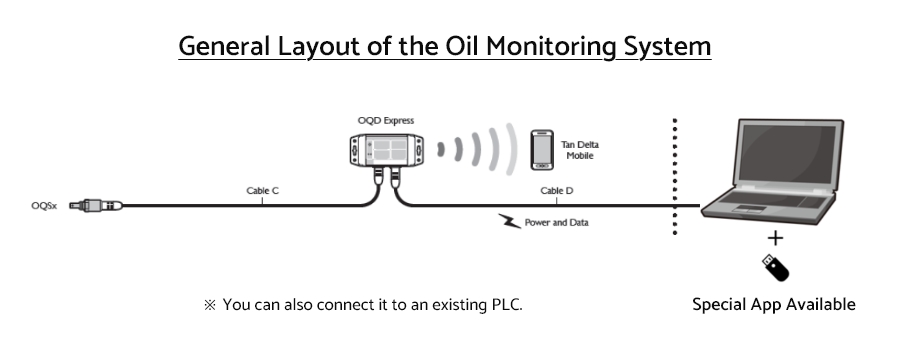

This oil quality sensor, equipped with advanced FSH™ core technology that enables constant monitoring of oil, applies an AC current to the oil 15 times per second and reads the electrical properties of the oil with a high accuracy of 0.001% (10ppm). This raw data is analyzed using a proprietary algorithm to produce a Tan Delta Number (TDN) that serves as an indicator of oil deterioration. By monitoring changes in the TDN, maintenance plans including as oil changes and filter replacements can be optimized. The TDN can be checked by connecting to the OQD Express display shown below or to a PLC already installed on site.

OQD Express

The OQD Express displays the oil condition value and temperature detected by the OQSx-G2 oil sensor in real time and keeps a log (up to 800,000). The OQSx-G2 is also equipped with Bluetooth, allowing data to be downloaded with a free app to a smartphone held within a 10-meter range. The device can be set with threshold values to give alarm signals. The device is airtight IP67 rated, compact and lightweight, and can be installed anywhere. It is also possible to link the oil sensor to an existing PLC without using the OQD Express.