DELTA-XERO

Removing nano-sized contaminants to always keep your oil cleaner than new oil

DELTA-XERO’s DX1000 series oil cleaners remove nano-sized (100 nanometers = 0.1 microns) contaminants as well as water from lubricating oil, hydraulic oil, and turbine oil using the advanced technology of cellulose capillary filters. These filters enable the oil to always stay cleaner than new oil. Varnish, which can cause various problems, is removed at the precursor stage, making it an ideal solution for machines troubled by constant damage to valves, spools, and other parts of the machine.

No Clogging!

Delta-Xero oil cleaners can remove contaminants the size of 0.1 micron to over 100 microns, as well as water (free and bound). One moth to several months of filtration can cause dirty oil to regain the cleanliness of new oil or even achieve greater cleanness. This is all done without interrupting the operation of your equipment or machine.

Unlike mesh-type filters which filter out particles above a certain size, Delta-Xero’s filter element uses its entire volume of cellulose capillary tubes to catch contaminants. This means the filter does not clog up.

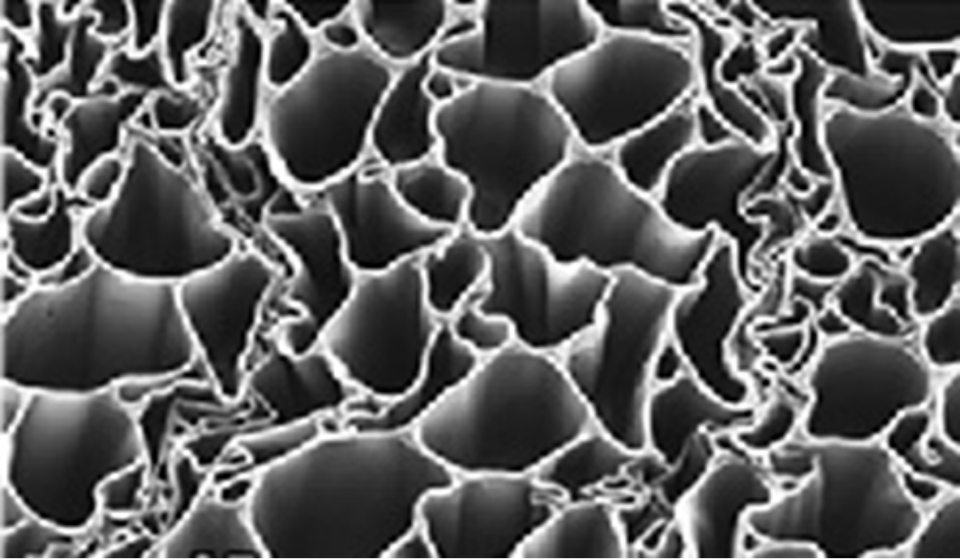

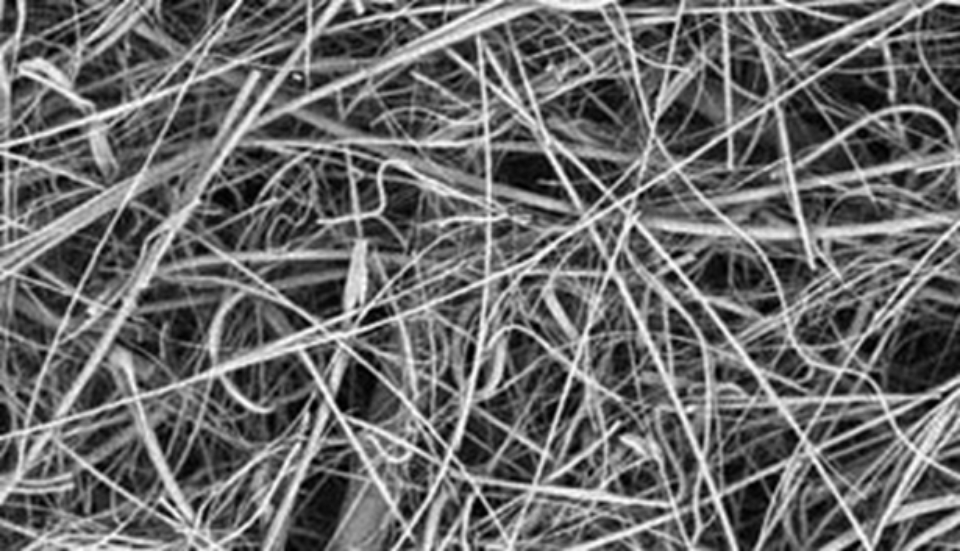

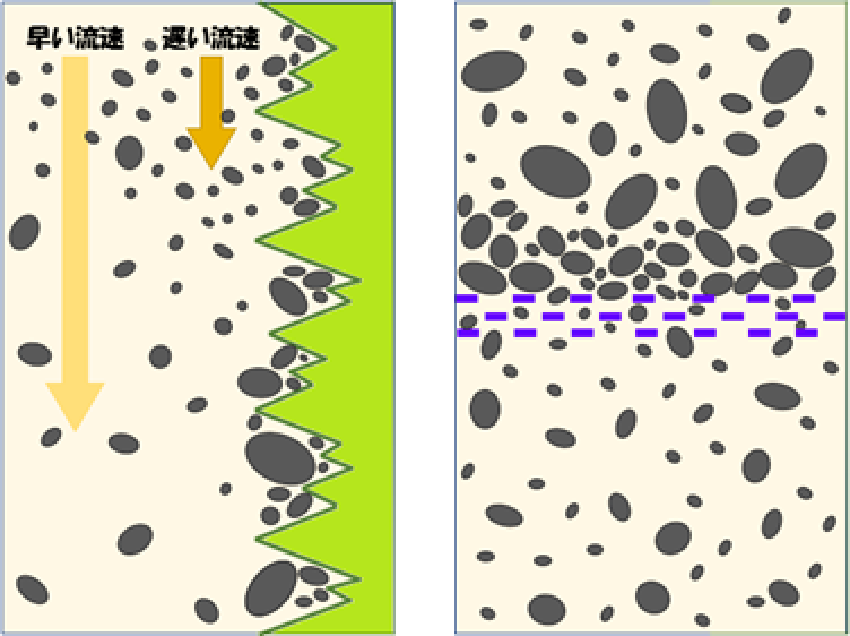

The cellulose capillary filters used in Delta-Xero’s oil cleaners are manufactured using patented technology that applies bioengineering of the tubular cellulose of trees, and has excellent properties unlike any other conventional oil filter. As shown in Figure B, a normal mesh type filter has a structure in which the fibers are compressed to prevent the passage of particles over a certain size, but the cellulose capillary filters allow oil to pass through the filter element at a relatively low speed as shown in Figure A, The cellulose capillary filter element can capture particles as small as 100 nanometers (= 0.1 micron) to those over 100 microns. The major feature of the “cellulose capillary filter” is that oil cleaning proceeds in a the opposite order than usual, first capturing the smaller particles that are missed by mesh-type filters before gradually capturing larger ones. This unique technology prevents clogging of the filter as the entire volume of the filter element is used to capture particles in the oil. The volume of particles adsorbed in the filter element can reach up to 3 to 5 kg.

These qualities cause the oil to become cleaner than new (unused) oil. Additionally, the extremely small particles which responsible for the increase in acid value, are removed, thus making it possible to control the acid value of the oil. Oxides that cannot be removed by ordinary filters agglomerate and accumulate to form sludge and varnish, but these precursors are captured before they can agglomerate, eliminating the formation of sludge and varnish. After several months of super-clean oil filtration, the lubricant oil’s flushing effect washes out the sludge and varnish that accumulated and adhered to the internal surfaces of the machine.

Figures C. and D. on the left show how particles are captured by a cellulose capillary filter vs a mesh-type filter. Figure C. shows that as the oil passes through the cellulose capillaries, the complex structure of the inner wall first captures the smaller before capturing larger ones. The relatively slow flow-speed allows the filter to capture particles more efficiently. The cellulose capillary filter achieves the optimum oil flow velocity by using a bypass system in which oil is drawn from the oil tank to the oil purifier bypass, purified, and then returned to the oil tank again. Since particles are collected on the inner surface of the cellulose capillary tubes, the flow of oil is not block as with mesh-type filters (as pictured in Figure D). The entire volume of the filter element can collect contaminants, and 3-5 kg of contaminants can be collected and retained in one filter element.

In addition, gelatinous (semi-solid) contaminants and water (free and bound), which would ruin a mesh-type filters, can be removed efficiently.

capillaries

The data below (Figure E.) is real example of oil cleaning in a hydraulic equipment (550 liters/68 cSt) in Japan. As a result of continuous oil cleaning using a cellulose capillary filter, the oil achieved a much greater degree of cleanliness than new oil. It is important to note that new oil contains a large amount of oxidants, micro-contaminants, and other oil deterioration factors, which means that from a maintenance standpoint it is best to avoiding oil changes (except for the necessary top-ups) in order to protect the machine.

| Sample Date | >4μm(C) | >6μm(C) | >14μm(C) | NAS Code | ISO 4406 Code | |||

|---|---|---|---|---|---|---|---|---|

| 2021/11/08 | 165 | 15 | 28 | 12 | 3 | 9 | 3 | 15/12/9 |

| 2020/05/19 | 518 | 16 | 100 | 14 | 15.0 | 11 | 5 | 16/14/11 |

| 2019/07/01 | 3890 | 19 | 159 | 14 | 8 | 10 | 7 | 19/14/10 |

E. Example of hydraulic oil cleaning with cellulose capillary filter (550 liters/68 cSt)

The greatest feature of the Delta-Xero oil cleaners is the cellulose capillary filters, and has a much simpler structure and is less expensive than electrostatic oil cleaners often used with the purpose of removing smaller contaminants. Electrostatic oil cleaners actually fact generate static electricity which causes particles in the oil to agglomerate, and the electrostatically charged particles can contribute to the formation of sludge and varnish. This can lead to damages to valves in the hydraulic system despite showing good oil analysis results. The Delta-Xero oil cleaners do not have these drawbacks, and effectively solve sludge and varnish problems.

Delta-Xero oil cleaners are already in use in Japan in metal processing, paper manufacturing, semiconductor manufacturing, and other machinery manufacturing. In Europe, where it is more widely used, these oil cleaners are found in a wide range of industries including wind power turbines, thermal and hydroelectric power generation turbines, construction machinery, ships, and offshore platforms. Additionally, by cleaning diesel fuel through these filter, NOx and other harmful exhaust gases are greatly reduced.

NAS grade, class 00

<No oil change for 5 years>

Products

DX1000 Series

Each product in the DX1000 series is designed and configured to maximize the excellent properties the cellulose capillary filter. The DX1000 series is capable of stable oil cleaning in small-scale oil systems as well as large turbine oil systems with oil capacities exceeding 100,000 liters. Off-the-shelf models include the DX1001, DX1002, DX1003, DX1004, DX1006, DX1009, and DX1012, each with 1 to 12 DXO cartridges to be fitted inside. For larger oil tank volume and higher oil viscosity, larger unites are more suitable. We can offer floor-standing units with trays as well as wall-mount types depending on what fits best at the installation site.

DXO Cartridge

The DXO Cartridge is a filter cartridge containing a cellulose capillary filter that removes 100 nanometers (=0.1 micron) of contaminants and water. Normally, the filter cartridge only needs to be replaced once a year for continuous use (we recommend replacing the filter cartridge after 3 months for the first time only, as oil is typically very dirty at the beginning of installation). Continuous oil cleaning will keep the oil in the system cleaner than new oil.

DX1525

The unit as well as the filter cartridge of DX1525 oil cleaner are more compact than the DX1000 series, and offer excellent cost performance for oil cleaning in machines with smaller oil volume (up to 1000 L at 32 cSt viscosity). The cartridge is made of the exact same material and as the DXO cartridge, so it has the same oil-cleaning capabilities such as removal of foreign matter as small as 100 nanometers (= 0.1 micron).

DX Powertrain

DX Powertrain is an oil cleaning system optimized for machines that primarily use diesel such as gas engines. It extends the life of engine oils which are generally heavily contaminated and require frequent change. This achieves significant cost savings and reduced downtime. Much like the standard DXO cartridge, the cartridge removes 100 nanometer (= 0.1 micron) particles and water, while also removing harmful siloxanes that occur in engine oil.